At Çağdaş Socks, we combine cutting-edge technology, full automation, and sustainable manufacturing practices to produce socks that redefine comfort, quality, and efficiency. Our production model unites precision engineering with eco-conscious innovation.

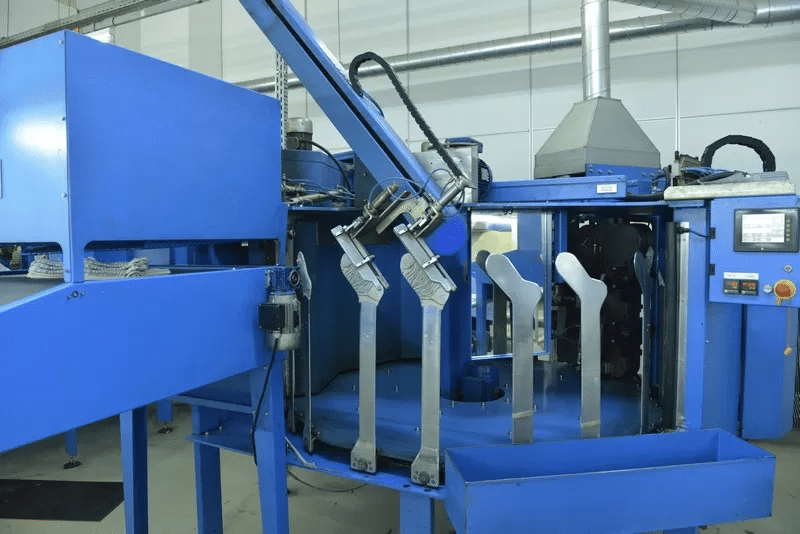

In our modern integrated factory, thanks to high-capacity and fully automated production lines, we ensure fast, efficient, and high-quality production.

With advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, we produce aesthetic and durable socks that meet customer expectations.

In addition, guided by our sustainability principle, we optimize our production processes by using energy-efficient machines and eco-friendly materials, minimizing both resource consumption and environmental impact.

Our vertically integrated production structure — from yarn selection to packaging — allows us to meet global demand with unmatched consistency, speed, and quality.

Our company has the capability to provide products and services with more than 700 machines.

The highest quality of yarns are carefully selected

Carefully knitted with the latest technology machines

Utilizing sustainable technologies and treatments designed for our customers’ needs

Strict quality controls are carried out at every stage.

Steamed and packed with outstanding to quality and sustainability.

Products are delivered the customers around the world.

Interested in partnering with a technology-driven manufacturer? Share your project details and we’ll provide a tailored proposal within 24 hours.