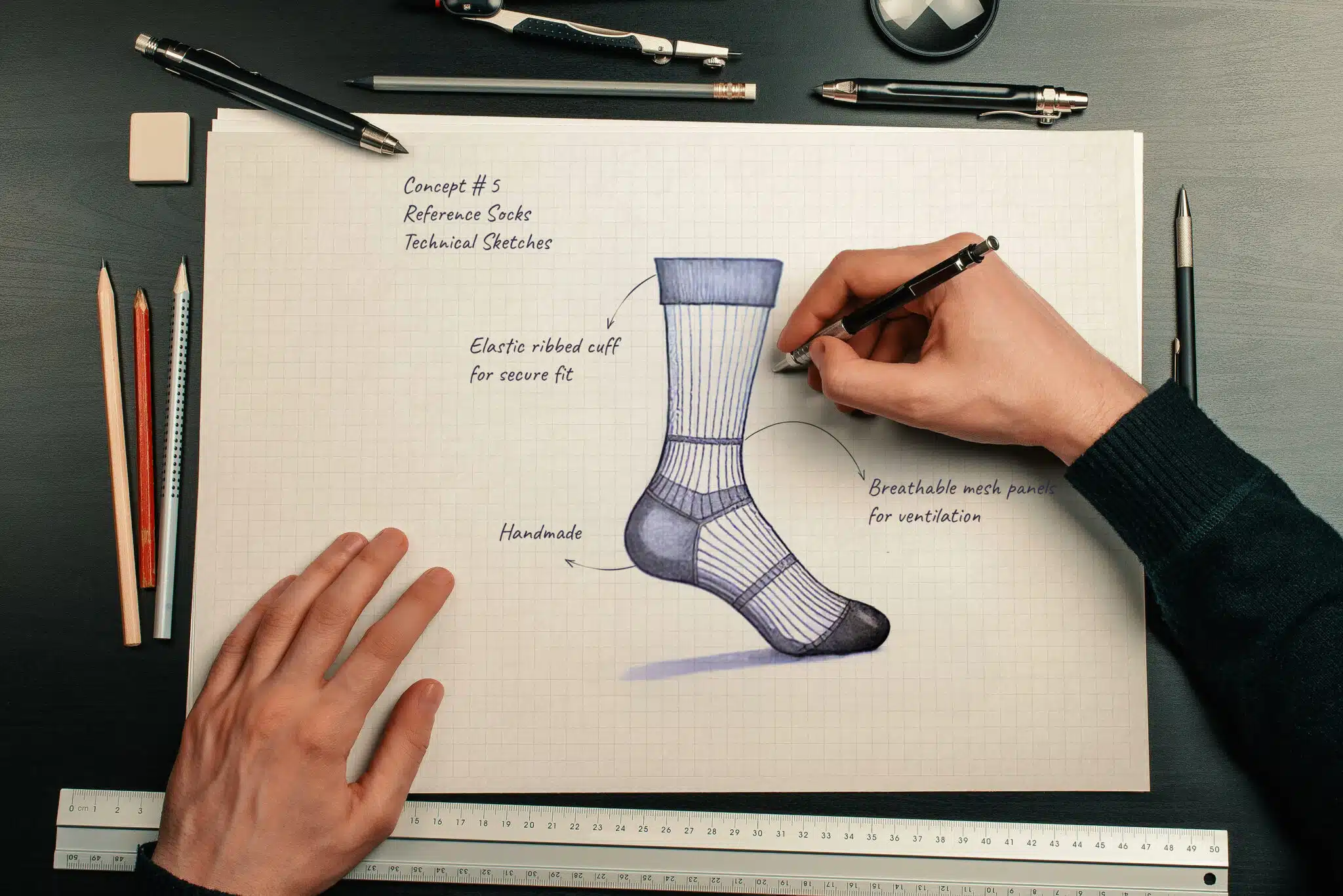

Every successful collection begins with a story. Sometimes it’s inspired by a mood, a season, or simply a color that feels right. At Çağdaş Socks, every pair we produce starts as an idea sketched on paper — and that idea travels through design, development, and production until it reaches a customer’s hands as a finished product. Turning creative vision into something real is both an art and a discipline.

Step 1: Inspiration That Speaks

A good collection always begins with listening — to people, to culture, to what’s changing in the world. Our creative team researches global trends, from streetwear and wellness to sustainability and performance. Then we translate those influences into stories: a palette inspired by coastal mornings, a texture borrowed from nature, a design detail that makes an everyday sock feel special.

We work closely with our partners during this phase. Some arrive with detailed sketches; others simply share a feeling or a concept. Either way, our design experts turn that inspiration into visuals, technical drawings, and color compositions that express the brand’s DNA.

Step 2: From Idea to Prototype

Once the story is defined, we move to development. Using advanced CAD knitting programs and 3D visualization tools, we build the first prototypes — translating yarn specifications, gauge counts, and design motifs into real samples. This stage is where precision meets creativity.

We test fit, texture, elasticity, and color accuracy, adjusting stitch density and yarn composition until the sock performs as beautifully as it looks. For many clients, this is their favorite part of the process — seeing an idea come to life for the first time.

Step 3: Production with Precision

When a design is approved, it’s time to scale. Our integrated factory in Istanbul runs over 700 state-of-the-art knitting machines, supported by automated finishing, washing, and packaging lines. Every pair is monitored through digital quality checkpoints that track consistency and performance.

Yet despite the scale, our mindset stays boutique. We treat each order — large or small — with the same care and attention to detail. This is how we maintain the “handcrafted” feel even in high-volume production.

Step 4: Finishing, Packaging, and Beyond

After knitting, each sock goes through washing, shaping, steaming, and final inspection. Then it’s packaged — often in recycled or FSC-certified materials — and prepared for shipment. But our process doesn’t end at the factory door. We assist our partners with logistics coordination, customs documentation, and retail-ready presentation.

From Vision to Reality

What begins as a simple sketch becomes something tangible — a product that represents creativity, quality, and responsible manufacturing. That transformation is what drives us every day at Çağdaş Socks. We don’t just make socks; we bring ideas to life, stitch by stitch, story by story.